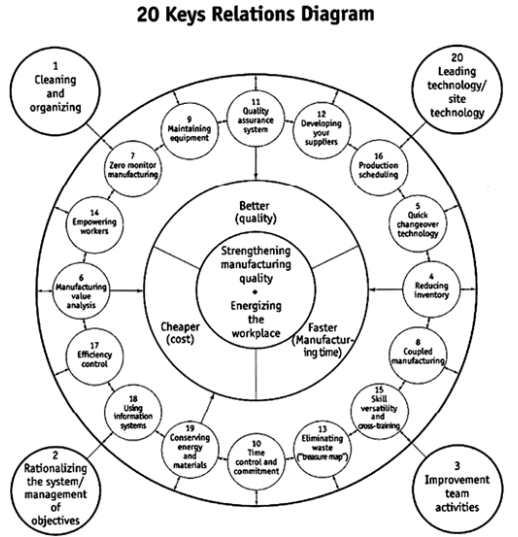

1. Clean and tidy. Everywhere and all of the time. 2. Participative management style. Working with all people to engage their minds and hearts into their work as well as their hands. 3. Teamwork on improvement. Focused on teamwork to involve everyone in enthusiastic improvements. 4. Reduced inventory and lead time. Addressing overproduction and reducing costs and timescales. 5. Changeover reduction. Reducing times to change dies and machines to enable more flexible working. 6. Continuous improvement in the workplace. Creating improvement as a ‘way of life’, constantly making work better and the workplace a better place to work. 7. Zero monitoring. Building systems that avoid the need for ‘machine minders’ and instead have people who are working on maintaining a number of machines. 8. Process, cellular manufacturing. Creating interconnected cells where flow and pull are the order of the day. 9. Maintenance. Maintaining of machines by people who work on them, rather than external specialists. This allows constant adjustment and minimum downtime. 10. Disciplined, rhythmic working. Synchronised total systems where all the parts work together rather than being independently timed. 11. Defects. Management of defects, including defective parts and links into improvement. 12. Supplier partnerships. Working with suppliers, making them a part of the constantly-improving value chain, rather than fighting with them. 13. Waste. Constant identification and elimination of things that either do not add value or even destroy it. 14. Worker empowerment and training. Training workers to do the jobs of more highly skilled people, so they can increase the value they add on the job. 15. Cross-functional working. People working with others in different departments and even moving to gain experience in other areas too. 16. Scheduling. Timing of operations that creates flow and a steady stream of on-time, high-quality, low-cost products. 17. Efficiency. Balancing financial concerns with other areas which indirectly affect costs. 18. Technology. Using and teaching people about more complex technology so they can use and adapt to it, bringing in the latest machines and making them really work. 19. Conservation. Conserving energy and materials to avoid waste, both for the company and for the broader society and environment. 20. Site technology and Concurrent Engineering. Understanding and use at all levels of methods such as Concurrent Engineering and Taguchi methods. Eins og hægt er að sjá af lyklunum er þetta mjög keimlíkt lean, við erum með cleaning and organizing sem er í raun 5s, einnig erum við með eliminating waste, empowering workers o.s.frv.

Ég myndi mæla sérstaklega með þessari bók fyrir þá sem eru að fara að innleiða lean í framleiðslu umhverfi, þetta mun ekki nýtast þeim sem eru í innleiðingarhugleiðingum á skrifstofu mikið.

0 Comments

Leave a Reply. |

AuthorViktoría og Lísa Archives

June 2021

Categories |

RSS Feed

RSS Feed